Are you thinking about starting your career in aviation as an aircraft mechanic? If so, you have probably asked yourself whether this career will truly fulfill you. There are many factors to consider before entering the aircraft maintenance field. Like any job in aviation, being an aircraft mechanic has its ups and downs. In this article we will review the key advantages and disadvantages of an aircraft mechanic career so that you can move forward with greater confidence and clarity.

Table of Contents

Pros of being an aircraft mechanic

1. Strong job demand

The global aviation industry is poised for significant growth. According to the International Air Transport Association (IATA), air traffic will double by 2037. As aircraft fleets expand, the demand for skilled mechanics to maintain them and ensure flight safety will also rise.

For instance, Boeing forecasts a steady demand for maintenance technicians in the coming years. The aerospace manufacturer estimates a need for around 716,000 new aircraft mechanics over the next two decades. Similarly, Boeing’s competitor, Airbus, predicts that the industry will require approximately 635,000 new maintenance technicians by 2037. This need arises from the growing fleet and the challenges posed by an aging workforce.

With such a strong demand for skilled professionals, now might be the perfect time to explore and enter this field.

2. Competitive salary across regions

The aviation industry is facing a critical shortage of skilled professionals. This challenge has prompted both aircraft maintenance and repair organizations (MROs) and airlines to rethink salaries and benefits for the maintenance personnel. They are eager to attract a new generation of specialists to the field.

Have you ever wondered what aircraft mechanics earn? Salary figures can vary widely depending on region, experience, and specialization. In the United States, starting salaries for new mechanics typically range from $45,000 to $50,000 annually. With more experience, salaries can rise significantly, reaching between $85,000 and $100,000 or even higher rates..

Location plays a crucial role in determining salaries. For instance, mechanics in California, Texas, and Alaska often earn more than their counterparts elsewhere. In California, the average salary for mechanics hovers around $80,000 per year.

What about Canada? Newly qualified aviation mechanics can expect to earn about CAD 55,000. Those in senior positions may see their salaries climb to CAD 95,000. Cities like Toronto and Vancouver typically offer higher compensation. For instance, experienced AMEs (Aircraft Maintenance Engineers, ed.) in Vancouver can make up to CAD 95,000 annually.

In Europe, the salary landscape is quite diverse. In the UK and Germany, aircraft mechanics generally earn between €45,000 and €60,000. However, in Eastern European countries like Poland and Romania, salaries start from €25,000, reflecting lower wage scales and cost of living.

3. Career growth opportunities

Aircraft mechanics have many exciting ways for career progression. As you gain experience or choose to specialize in areas like avionics, hydraulics, or composite materials, you can unlock higher salaries and better job opportunities.

Many mechanics also choose to step up into managerial or supervisory roles. With enough experience and additional certifications, mechanics can transition into quality assurance roles, safety management, or become supervisors of maintenance teams.

But that is not all! Earning certifications like FAA Inspection Authorization (IA) or obtaining additional ratings (such as for turbine engines or advanced avionics) can significantly enhance your prospects. These qualifications not only make your resume stronger but also help you get better job opportunities.

For example, have you ever considered becoming a Designated Airworthiness Representative (DAR) for the FAA? This prestigious role can lead to high-paying opportunities within regulatory agencies, allowing you to play a vital role in ensuring aircraft safety.

4. Job variety and flexibility

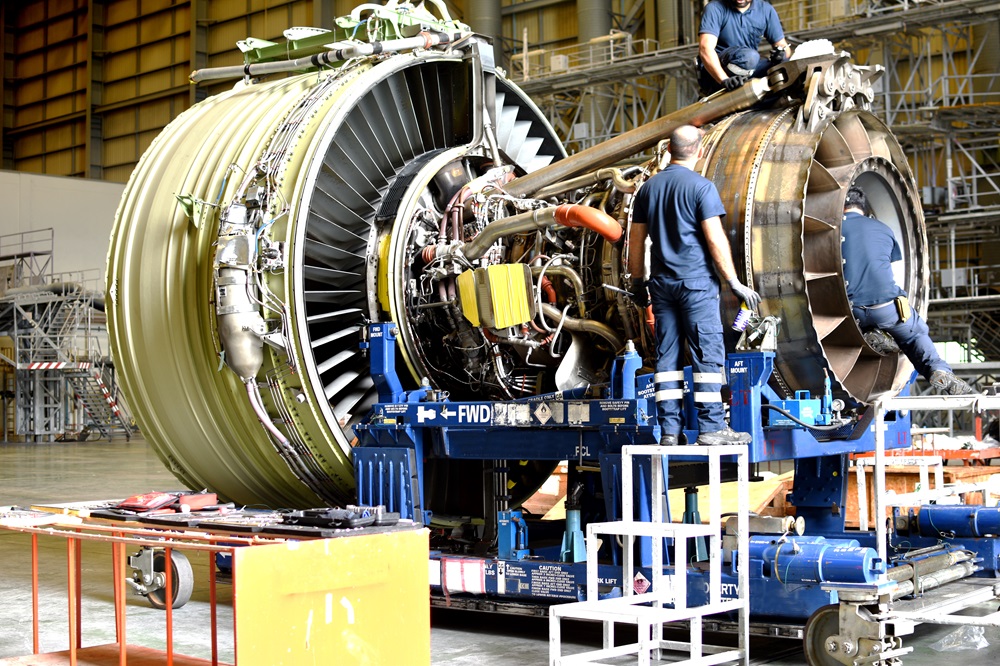

Aircraft mechanics work on a wide range of aircraft types, from commercial airliners and private jets to helicopters and military planes. This range keeps the work exciting and allows mechanics to specialize in specific systems or aircraft types.

In addition to the variety of aircraft, the flexibility of working in different locations is another appealing factor to many in this profession. Some mechanics are based at major international airports, while others find rewarding opportunities with private companies, defense contractors, or even work on-call at smaller airports.

Furthermore, the shift structures in many aviation jobs -such as 12-hour shifts or a 7-on / 7-off schedule – can provide extended time off. This flexibility allows for a good work-life balance, making the role even more attractive to those looking to pursue personal interests or spend quality time with family.

5. Global mobility

One of the major advantages of being an aircraft mechanic is the ability to work anywhere in the world. For instance, FAA-certified mechanics in the US can find jobs abroad after completing the necessary license conversion processes, especially in countries that recognize FAA A&P licenses. Likewise, those with EASA Part-66 licenses are in high demand throughout Europe and beyond. The license conversion process may involve additional training or exams, but it is a pathway to global mobility.

It allows mechanics to experience diverse environments. Whether you dream of working for airlines in bustling hubs like Dubai or Singapore or prefer the charm of smaller airports in rural areas, the possibilities are endless. With strong demand in regions like the Middle East and Asia, foreign mechanics can enjoy tax-free salary packages while exploring new cultures.

Cons of being an aircraft mechanic

1. Licensing requirements and conversion challenges

One of the primary considerations for aspiring aircraft mechanics is navigating the licensing requirements and conversion challenges associated with different jurisdictions. While the profession offers excellent career opportunities, transitioning between systems like the FAA and EASA can be complicated. Mechanics moving from one regulatory environment to another may need to complete additional exams or practical assessments to meet local standards.

For instance, an FAA A&P mechanic looking to work in Europe might face the hurdle of passing EASA’s theory and practical exams. This process can be not only challenging but also costly and time-consuming. The fees for exams and potential retraining can add up, creating a financial barrier for some. Additionally, the need to familiarize oneself with different regulatory requirements and procedures can be overwhelming.

However, overcoming these challenges can lead to significant rewards. Successfully obtaining the necessary licenses opens up a wealth of job opportunities across various regions, especially in high-demand markets. The ability to work internationally can be a major advantage for those willing to invest time and effort into the conversion process.

2. High-pressure work environment

Aircraft mechanics are responsible for the safety of passengers, crew, and the aircraft itself. Their responsibilities are extensive. They include everything from routine inspections to complex repairs. Even small errors can result in significant risks, leading to high-stress levels, especially when working under strict time constraints.

Mechanics frequently operate under the oversight of regulatory bodies like the FAA or EASA, which impose stringent safety standards that must be adhered to at all times. These regulations are designed to ensure that maintenance procedures meet high-quality benchmarks. When unexpected repairs arise, particularly during tight flight schedules, the pressure intensifies. Mechanics must act quickly and efficiently, often racing against the clock to ensure that aircraft are ready for takeoff without compromising safety.

The environment in which aircraft mechanics work contributes to stress. They may face noisy hangars, crowded workspaces, and the need to communicate effectively with other team members and flight crews.

3. Physical demands and health risks

Aircraft mechanics face significant physical demands in their line of work. Their tasks often require them to kneel, bend, or stand for extended periods, which can lead to fatigue and discomfort. The physical nature of the job necessitates a strong, resilient body, as mechanics frequently perform tasks in awkward positions that can strain muscles and joints.

Moreover, working outdoors exposes mechanics to extreme temperatures. Whether in the heat of summer or the chill of winter, they must adapt to the elements while maintaining focus and productivity, particularly at airfields where conditions can be unpredictable. These environmental factors can affect both physical comfort and overall job performance. Injuries, such as muscle strain, are also more common due to the physical demands of the job!

In addition to the physical challenges, aircraft mechanics are often exposed to hazardous materials such as fuels, oils, and various chemicals. Prolonged contact with these substances can pose serious health risks, including respiratory issues and skin irritation. The noise levels in aircraft maintenance environments can also be significantly high, especially near engines and turbines.

4. Varying salary based on location and experience

While the overall salary prospects for aircraft mechanics are strong, pay varies significantly based on geographic location and experience.

In areas with a high cost of living or major metropolitan regions, salaries tend to be higher. This is due to the demand for skilled mechanics in busy aviation hubs. These hubs usually have many airlines and maintenance facilities. Conversely, regions with fewer job opportunities or a lower cost of living may offer lower salaries. This reflects local economic conditions and competition for jobs.

The type of employer also affects salary. Mechanics working for major airlines or large MRO facilities often receive better compensation and benefit packages. In contrast, those working for smaller operators or independent shops may earn less. Additionally, mechanics in the military sector have different salary structures and benefits, which can be more attractive to some.

5. Certification costs

Certification and training costs for aircraft mechanics can vary widely. For instance, initial training for an Airframe and Powerplant (A&P) certification can range from several thousand to tens of thousands of dollars, depending on the program and institution. After obtaining certification, mechanics must often complete recertification exams or acquire additional qualifications. This might include endorsements for new types of aircraft or specialized systems like avionics. These endorsements typically require not just study materials and exam fees, but also practical training sessions.

Mechanics must invest in continuing education to keep their skills sharp and relevant. Some estimates suggest that ongoing training can cost several hundred to a few thousand dollars every few years, depending on the specific courses or certifications pursued. For example, attending a specialized avionics training course can cost anywhere from $1,500 to $5,000.

Recertification is also a critical aspect of maintaining credentials. For FAA-certified mechanics, recertification is generally not mandated as a blanket requirement. But in the case of EASA-certified mechanics, revalidation of licenses is necessary every five years.

Deciding to become an aircraft mechanic is a big choice that involves weighing both rewards and challenges! There are diverse opportunities for growth in the field. The rising demand for skilled mechanics is driven by the rapid expansion of the aviation industry and an aging workforce, which further enhances job security for newcomers. As such, pursuing a career as an aircraft mechanic can be a promising path for those seeking stability and opportunities for advancement.